With drupa so close on the horizon, printer manufacturers have been keeping their powder dry. Rather than introducing new machines so close to the main event they have preferred to focus on enhancements and tweaks to make machines more appealing for different applications. Companies such as Ricoh, HP and Kodak fall into this bracket, but Xerox has introduced a completely new and extremely interesting device.

Ricoh introduced its Pro C901 Graphic Arts edition machine to provide an engine suitable for mid-range production. It prints at 90 A4 pages per minute in full colour and is an enhanced version of the C901, able to print on substrates up to 300gsm. HP has steadily enhanced and upgraded its line of Inkjet Web Press machines, with the latest model, the T400, introduced in March able to print 183m/min. Kodak seems to be doing well with its Prosper technology, having installed this high-speed continuous flow ink-jet press at a number of European sites. These are all sort of new engines, but they aren't quite so exciting as the Xerox CiPress which was introduced in September, and is based on an unique ink-jet printing technology.

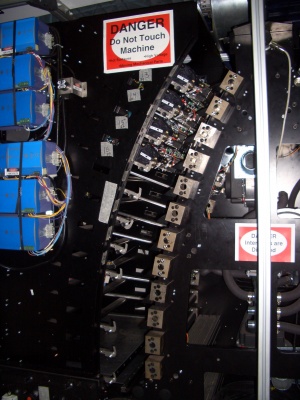

The CiPress is already in action in the USA. Note the empty

bays which we expect to see filled come drupa

The Xerox CiPress is interesting because it is the only waterless ink-jet press on the market. This continuous feed engine jets hot-melt phase-change inks and prints 600dpi. According to Xerox, the nature of the inks and head design mean that dot placement is highly accurate. Samples we have seen of direct mail work look very pretty indeed, as you might expect. However Xerox reckons this is only the beginning of what they can do with its phase-change inks.

The CiPress runs at 152m/min so it can print 2,050 full colour A4s per minute on substrates 50 to 160gsm. Xerox has stitched together seven of its own piezo drop-on-demand heads into a 520mm array. There are 56 print-heads altogether with 14 heads printing each of the four colours. The 50,000 jetting nozzles are monitored using a closed-loop control system and a scanning bar borrowed from the iGen4. The scan bar looks for misfiring nozzles so that adjacent nozzles can be used to compensate for them. The scan bar also tracks colour-to-colour registration on the fly, instructing the heads to move both vertically and horizontally to ensure that all four colours are printed in register. An impression roller at the end of the press flattens out the droplets, but does not cause any dot gain. Xerox has had best results printing on uncoated papers which are better suited to the waxy dots. However, Xerox is working to improve performance on coated stocks. This is a scalable technology so we expect to see additional models at drupa both narrower and wider. We also expect to see a model able to print more than four colour inks.

Because CiPress is a waterless technology Xerox should have greater scope for substrates and for price competitiveness with similarly quick engines. For instance there is no need for drying or moisturising units, which might mean a lower price tag. The CiPress is positioned for a variety of applications but we think it could be a viable contender for digital newsprint, competing with the Kodak Versamark and Océ Jetstream engines. The CiPress is also positioned for transaction, direct mail, manual and book printing.

The first installation of the engine at dmh Marketing Partners in Iowa, USA, is being used for direct mail. This company produces 85 million pieces of direct mail per month and is a longstanding Xerox customer. There is also a European installation of the CiPress, but Xerox can't yet tell us where it is or what sort of work it is producing.

The machine is one of many going for the same sorts of markets. This is very good for customers, since it means they have plenty to choose from. But it also means that a cutthroat business could get uglier and matters will get worse next year when we will see more ink-jet introductions, plus larger-format xerographic engines.